How to Get the Right Compliance Markings to Clear Customs

- By Grace

- Updated on

Picture this: your product is flawless, your shipping documents are perfect, but a single, missing, or incorrectly placed label on the final retail box gets your entire shipment seized at customs. Or worse, it triggers a mandatory product recall that wipes out your inventory. This isn't an exaggeration; it's a critical and often overlooked part of international trade compliance.

Regulatory authorities see the little icons and warnings on your packaging as the final, non-negotiable proof of compliance. A missing RCM mark in Australia isn't just a mistake; it's a violation. This is a massive vulnerability in your supply chain risk management.

At KLCOSY, we believe a true manufacturing partnership is built on understanding these critical details. It requires a process that treats a packaging label audit with the same obsessive quality control as the product's internal electronics. Let's explore why this final piece of the puzzle is so important and the system we use to ensure your product is 100% compliant the moment it leaves our factory.

So, How Can a Tiny Label Become Such a Huge Liability?

You're focused on the big picture: market strategy, pricing, and product features. The packaging label seems like a minor detail. But in reality, those tiny symbols carry more legal weight than almost any other element of your product.

I'll never forget what a veteran importer told us about a previous supplier. They failed to update a battery warning label after a minor design change. The error was caught during a random market inspection, resulting in a three-week sales suspension while the importer scrambled to apply corrective stickers to thousands of boxes. The final cost? Over $50,000 in lost revenue and a massive headache.

Your packaging is literally a billboard for your product's legal status, and any error is a public announcement of non-compliance. A missing RCM mark in Australia or an incorrect WEEE symbol in Europe is an instant red flag for regulators, triggering customs holds, mandatory relabeling, or even a forced product recall.

- The Mandate of the Mark: Regulatory compliance markings like the RCM mark (Australia), CE mark (Europe), and FCC mark (North America) are not decorations; they are legal affirmations of compliance. A partner's job is to know which marks apply to your market and ensure they are present and correctly placed.

- Safety Warnings: Your First Line of Defense. Mandatory product safety warnings—like those for lithium-ion batteries or general electronic safety—are critical for protecting your business from liability claims.

- Placement and Clarity Matter. Compliance rules often dictate the exact size and location of these marks. An RCM mark that's too small or hidden on the bottom of the box can be a technical violation, leading to the same penalties as a completely missing one.

Key Takeaway: Packaging marks are not details; they are legal requirements. Errors in their presence, correctness, or placement can lead to severe financial penalties and market access restrictions.

Our Proactive Shield: How We Get Your Packaging Right, Together

Let's be honest, the sheer volume of global regulatory marks is overwhelming. Keeping current on every rule change in every market is virtually impossible for a single importer. This is a job that must be delegated to a partner with the specialized systems and expertise to manage it for you.

We had a new e-commerce client who sent us a long, confusing list of requirements for the Canadian market. Our compliance team quickly reviewed it, cross-referenced it with our internal Canadian checklist, and confirmed that our standard packaging already met 95% of their needs. We only had to add a single minor icon—a change that was managed and completed on our end within 24 hours, with a final proof sent for sign-off.

Our approach to product packaging compliance is built on a clear, shared, and auditable process we call the KLCOSY Compliance Gate.

- Your Input is Critical: The Markings Checklist. You're the expert on your market. You provide us with a consolidated checklist of all the compliance marks, warning labels, and safety icons you need. This becomes our guiding document.

- Our Multi-Stage Artwork Review. Before anything goes to print, your packaging artwork undergoes a mandatory review. We check it against our internal, country-specific database for common requirements and then double-check it against the specific checklist you provided.

- Final Proof Sign-off. We send you the final, high-resolution proof with all compliance marks highlighted in a review layer. We require your explicit, written sign-off before a single box is printed. No surprises, no guesswork.

Key Takeaway: A structured, multi-stage review process, combining your market knowledge with our compliance expertise and ending in a formal sign-off, eliminates ambiguity and ensures accuracy before production begins.

The Final Check: Verification on the Production Line

The artwork is approved, the ink is dry. This is the last chance to catch an error before your product is sealed in its box. What system is in place to verify that the markings on the final product are exactly what was approved?

We once audited a potential supplier for a corporate client. They had a "packaging inspection" step on paper, but in practice, the floor manager just gave the boxes a quick glance. We discovered that a whole batch of products had the wrong version of a logo because someone had loaded the wrong sticker roll. It was an error that would have cost tens of thousands to fix if it hadn't been caught.

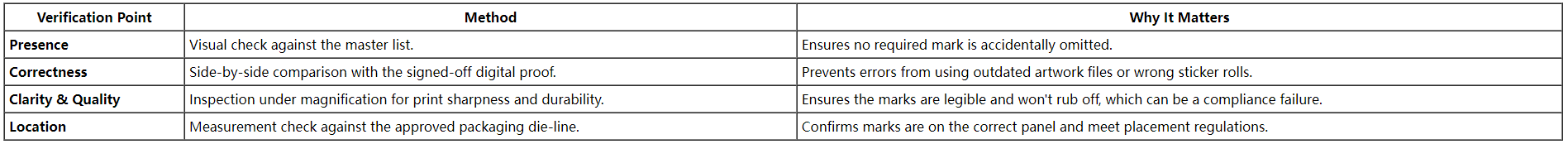

The final packaging inspection is where our commitment to compliance becomes a physical reality. It's a mandatory, documented step in our final QC process. Our inspectors use a physical and digital check-sheet to verify these key points for every batch:

This isn't just a casual look; it's a systematic, auditable part of our quality control checklist that is linked to every product's unique serial number, creating a permanent record of compliance for your batch.

The silence of a missing label is the loudest danger in your supply chain. Don't let a tiny detail become a catastrophic liability. Partner with a manufacturer like KLCOSY who manages the complexity of global compliance for you, ensuring your product is safe, legal, and ready for sale from the moment it leaves the port.

Ready to eliminate compliance risk from your supply chain? Let's discuss your market's specific labeling needs, and we'll show you exactly what our secure, multi-stage approval process looks like.