Custom Massager Production Time: Why Does It Take 2-4 Weeks?

- By Grace

- Updated on

You’ve got a killer product design ready to go, but a nagging fear is holding you back: will customization derail your launch? Every day of delay feels like a direct hit to your market entry, and that's a risk you just can't afford. Here’s the thing—managing the custom massager production time shouldn't be a gamble. It should be a science.

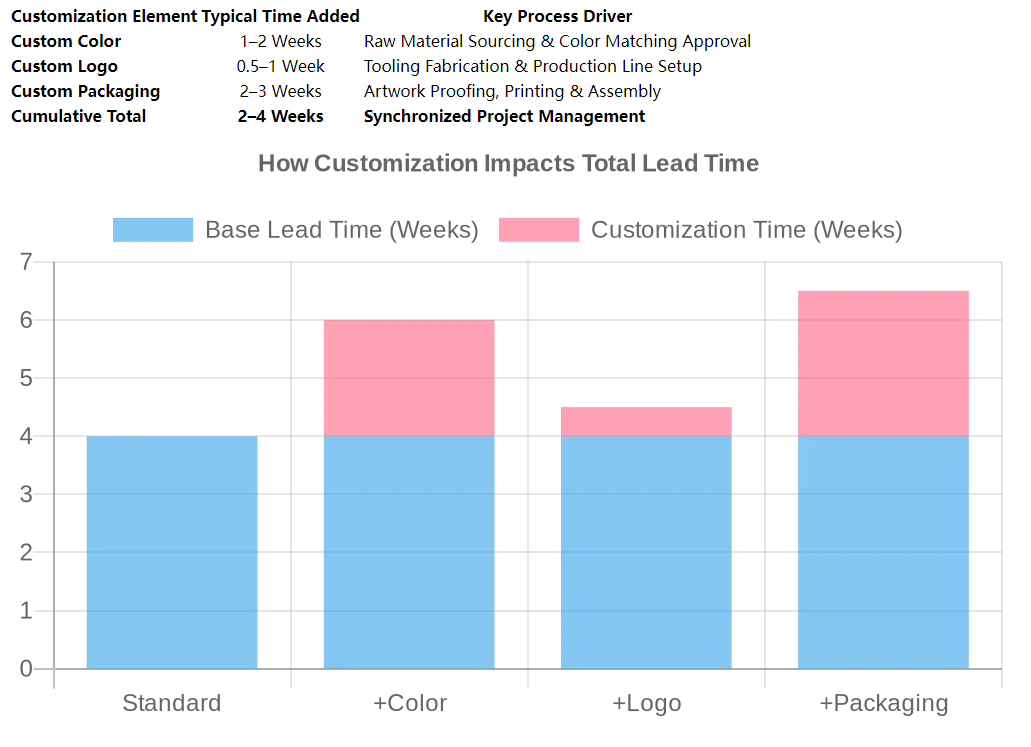

So let's get this out of the way first: customizing your private label massager electric with a unique color, logo, and package will add between 2 to 4 weeks to your production timeline. But that's not a sign of a slow factory. It's the mark of a deliberate, quality-controlled process that any good China massager supplier follows. Understanding where that time actually goes is the first step to mastering your schedule.

Let's break it down.

So, Why Does Customization Actually Extend Lead Times?

You’re always told customization takes longer, but it's rare to get a straight answer on exactly why. That lack of transparency is what creates uncertainty. The real answer isn’t on the factory floor; it’s in the entire supply chain that has to be built from scratch, just for your product.

A custom order isn't just a small tweak; it kicks off three entirely new processes:

- Sourcing specialized materials

- Creating dedicated machine tooling

- Running a separate design approval loop

I remember a client, a major distributor for a retail chain in the EU, telling me that seeing our breakdown of these phases for their ODM massager order was the "aha!" moment. It gave them the confidence to lock in a major promotional deadline.

Think of it like this: a standard product is like a restaurant's most popular dish. The ingredients are always stocked, and the cooks have the recipe down to a reflex. It’s a smooth, repeatable flow. Requesting a custom element is like asking the chef to create a brand-new special. Suddenly, there's a whole new process. Sourcing a specific Pantone color isn't just mixing paint; it means finding the right pigments and running test batches to ensure the color is perfect. That’s how you avoid "quality fade" down the line. This structured approach is what separates a reliable partner from one who just tells you what you want to hear. It turns potential chaos into predictable milestones.

Your Timeline, Broken Down Step-by-Step

Vague estimates are useless when you're trying to plan your marketing and finances. If you're asking, "how long does custom massager production take?", you need concrete data. Here’s a transparent look at where the time goes, based on each layer of customization you add.

I was on a call with a US-based corporate wellness client who was thrilled because our detailed timeline table for their branded wearable massagers allowed them to perfectly sync their arrival with their company's annual health week. It made the entire program a massive success.

To give you that same clarity, we’ve mapped out the timelines for each customization type. While some of these happen at the same time, each has its own non-negotiable time cost.

The Material Sourcing Challenge: Custom Colors (1-2 Weeks)

This is all about raw materials. For our standard colors, we have a constant supply. But if you want a specific Pantone color, we have to source new pigments and create a new plastic masterbatch. That involves ordering samples, getting your sign-off, and then manufacturing the full material batch—all before your product even hits the main production line.

The Tooling and Setup Phase: Logo Application (About 1 Week)

Your logo needs a new tool. Whether it's a silk-screen plate or a laser engraving fixture, that tool has to be custom-made and tested. Then, we have to take a machine offline, calibrate it with the new tool, and run checks to make sure the logo is crisp and perfectly placed every single time.

The Parallel Production Stream: Packaging (2-3 Weeks)

Think of custom packaging as its own separate manufacturing project. Finalizing artwork, creating printing plates, and assembling the boxes all happen alongside your massager production. This stream has its own lead time, and we manage it so the finished boxes arrive just as your massagers are passing their final quality check.

How You Can Minimize Delays and De-Risk Your Launch

Let's be real: the biggest fear isn't the planned delay. It's the surprise one that throws your entire launch into chaos. These surprises almost always come from miscommunication or last-minute changes. The only way to prevent them is with a proactive, collaborative process.

The single most powerful thing you can do to control your timeline is to finalize all your design assets before production begins. A Canadian retail partner told us our simple pre-production checklist cut their internal approval time in half, which meant their big seasonal order for a private label massager electric arrived with weeks to spare.

Once you approve a design for mass production, that's a critical handoff. Any change after that point—even a small one—can cause a ripple effect. A tweak to a Pantone color could mean we have to scrap the raw materials and start over. These aren't minor adjustments; they're process resets. To prevent this, we've built a framework based on shared responsibility. It’s a simple system that works.

Your Role: Make Decisions Early and Stick to Them

Your biggest impact on the timeline comes from the speed and finality of your design decisions. The faster we get finalized, print-ready files and confirmed color codes, the faster we can start procurement and tooling. It’s that simple.

Our Role: Manage the Project Transparently

Our job is to give you a clear project timeline from day one and keep you updated at every milestone. We handle the complex job of making sure all the different customization streams—product, logo, packaging—all come together perfectly for final assembly.

Bottom line? That extra 2-4 weeks isn't a sign of chaos. It's the sign of a structured, professional process. By understanding and planning for these stages with a transparent partner, you can build a unique product and a reliable supply chain you can actually count on.