Prevent Massager Component Fade with a Transparent Supply Chain

- By Grace

- Updated on

Your "golden sample" ran on a premium Japanese motor that you meticulously tested and approved. But six months and 10,000 units later, customer complaints about noise and failure are surging. A product teardown reveals the gut-wrenching truth: the motor has been swapped for a cheaper, uncertified alternative without your knowledge.

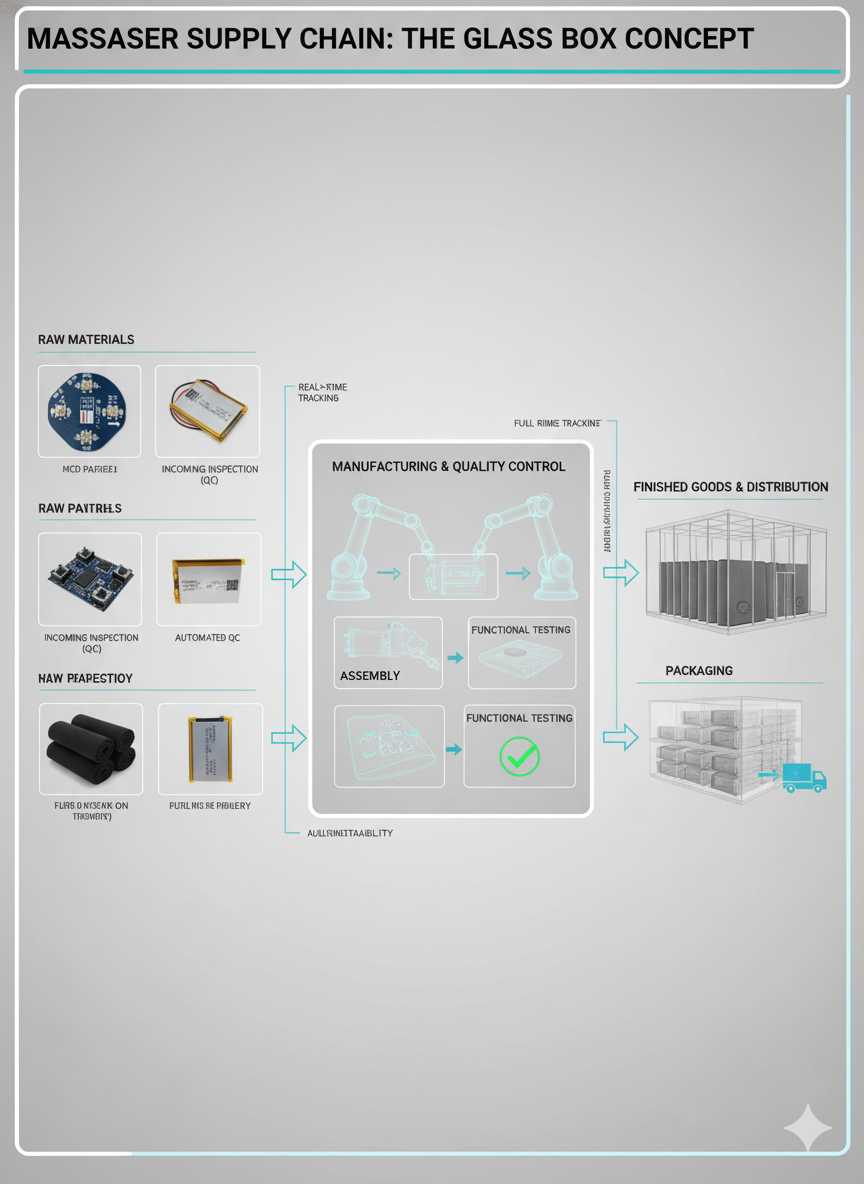

This is "Component Fade," a specific and devastating form of Quality Fade where a supplier secretly degrades the quality of raw materials to pad their margins. At KLCOSY, we operate on a principle of total transparency—what we call a "Glass Box" supply chain. We believe you have the right to know exactly what goes into your product, from the first unit to the last.

This guide pulls back the curtain on our massager supply chain transparency. I'll detail our rigorous Incoming Quality Control (IQC) process, explain how we lock in your Bill of Materials (BOM), and show you the exact protocol we follow to give you an auditable, predictable, and risk-free manufacturing partnership.

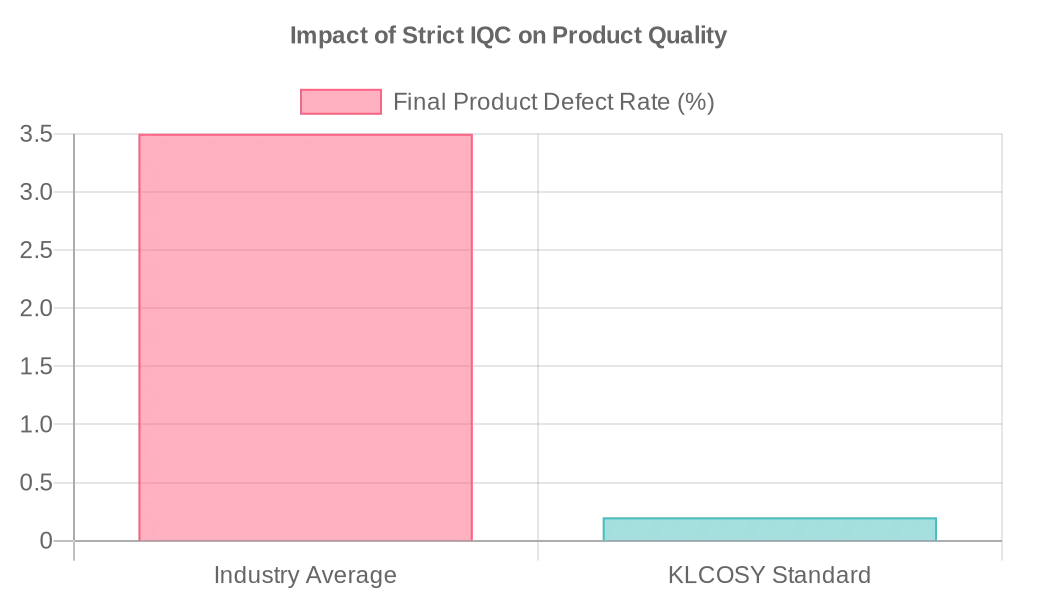

Are Your Raw Materials *Really* Being Inspected?

You approve a product based on its core components, but a hidden swap deep in the supply chain can destroy your brand's reputation without you ever knowing. Trusting a supplier's promise is not a strategy; it's a gamble.

A B2B partner who supplies a national spa chain told me they switched to us after their previous supplier's massagers started failing just after the warranty expired. A teardown revealed a cheaper motor had been substituted without notice. This is why rigorous massager component verification is so crucial.

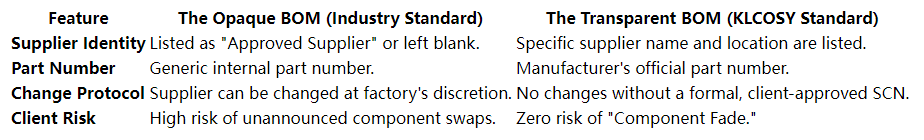

The typical manufacturing supply chain operates like a "black box." You approve a component, and it disappears into the factory, with no verifiable proof that the same component is used in every batch. At KLCOSY, our Incoming Quality Control (IQC) for massagers is the first wall of defense. Before any raw materials are accepted into our inventory, they are subjected to a rigorous inspection. For a motor, we test for RPM consistency, torque under load, and noise levels. We demand and verify the supplier's own Certificate of Conformance (CoC) for every single batch. This data is recorded in a formal IQC report, linked to the production lot, and available for you to audit at any time.

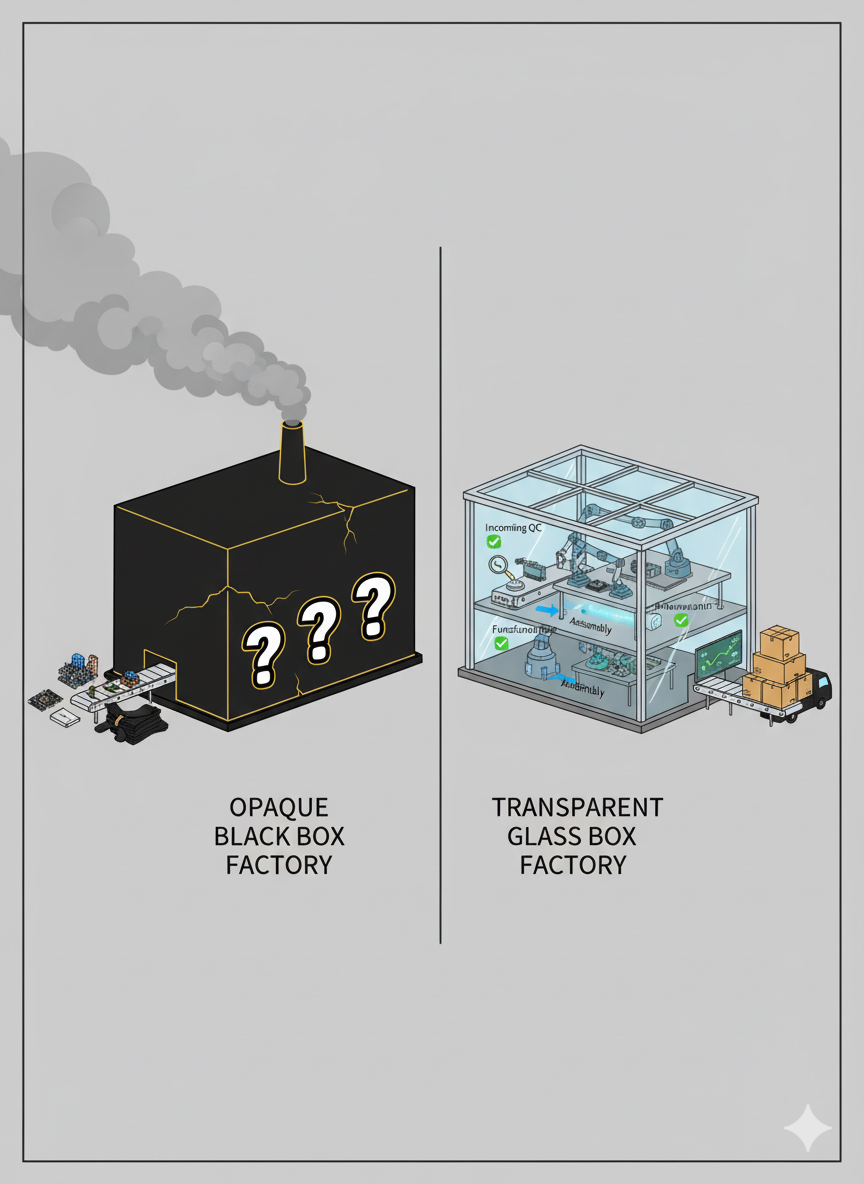

The Bill of Materials (BOM) Is a Contract. Period.

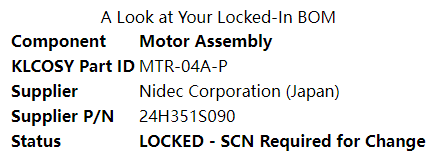

We treat the massager Bill of Materials (BOM) not as a guideline, but as a binding contract. Each critical component is listed with its supplier, part number, and key specs. This document becomes the single source of truth for your product.

What Happens if a Key Component Fails Our Inspection?

Let's play out a real-world scenario. A batch of 5,000 batteries arrives for your order, but our IQC tests show their charge-cycle life is 15% below the approved spec. What would your current supplier do? Many would be tempted to approve the batch to avoid a production delay.

Our protocol is different. We quarantine the entire batch, notify you immediately with the test data, and begin sourcing a replacement. The procurement manager for a corporate wellness supplier told me something that stuck with me after we proactively notified them of a 3-day delay. "For the first time," he said, "a supplier protected our quality instead of just protecting their timeline."

A component failure at IQC is a critical test of a supplier's integrity. A minor, well-communicated delay is always preferable to a major field failure or recall down the line. Pushing a substandard component into production to meet a deadline is a short-sighted decision that ultimately costs far more in the long run. Our supplier quality control process is designed to protect your long-term success, not just our short-term schedule.

So, Can You Lock In Your Critical Component Suppliers?

You've done the due diligence on the motor and the battery. You know they are reliable. How do you prevent your supplier from changing them six months from now without you knowing? Yes, you can—through a formal process that makes unauthorized changes impossible.

The ultimate protection against "Component Fade" is a contractually-enforced Supplier Change Notification (SCN) process. At KLCOSY, this is a standard part of our partnership agreement for sourcing private label massagers. Once the Bill of Materials is finalized and approved, it is locked. No component supplier can be changed without initiating a formal SCN. This document outlines the proposed change, the reason for it, and includes full specs and samples of the new component. The change cannot be implemented until you have tested the new component and provided your explicit, written approval. This process puts you in complete control of your product's DNA.

A transparent supply chain isn't just a feature; it is the fundamental basis of a reliable manufacturing partnership. We eliminate the risk of "Component Fade" by giving you an auditable, data-driven system. From providing IQC reports for every critical batch to locking your BOM and requiring your approval for any changes, we give you unprecedented control over your product quality. We invite you to demand this level of transparency from us.