DFM for OEM Products: A Guide to De-Risking Your Launch

- By Grace

- Updated on

Your OEM design is the blueprint for your brand's next big success. It's the culmination of your market research and vision. But a blueprint, no matter how brilliant, is not a building. The journey from a perfect CAD file to a flawless physical product is where things get tricky, where the laws of physics and the realities of plastic injection molding can challenge even the best designs.

I like to think of our role this way: you're the architect; we're the structural engineer. You create the vision; we make sure it can be built robustly, efficiently, and without compromising an ounce of quality. This collaborative process is called Design for Manufacturability (DFM), and it is the single most critical step to de-risking your entire OEM product development process. It's our promise that your blueprint will become a landmark product, not a costly lesson.

In this guide, I'll walk you through our DFM process—a transparent engineering review designed to align your design with the realities of high-volume production. I'll show you how we identify and solve potential issues before they become expensive problems, ensuring your product is a success from the very first unit.

So, Why Does a "Perfect" Blueprint Create a Flawed Product?

Your 3D-printed prototype is flawless, and the CAD model is perfect. Yet, when the first injection-molded samples arrive, they're marred by subtle but unacceptable defects—sink marks, warping, or weak points.

Here’s the problem: a blueprint doesn't account for the intense pressures and thermal dynamics of the injection molding process.

I remember an OEM partner who came to us after their previous supplier produced samples with visible sink marks over every single internal screw boss. Their design was beautiful, but it ignored the fundamental rules of plastic flow and cooling. The journey from a digital file to a physical object involves transforming molten plastic into a solid part under extreme conditions. As the plastic cools, it shrinks. A design that looks perfect on screen can create a manufacturing disaster if it doesn't respect this simple fact. These aren't random flaws; they are the predictable consequences of a design that isn't harmonized with the manufacturing process. Our DFM analysis is designed for preventing molding defects by finding elegant solutions before they become expensive tooling mistakes.

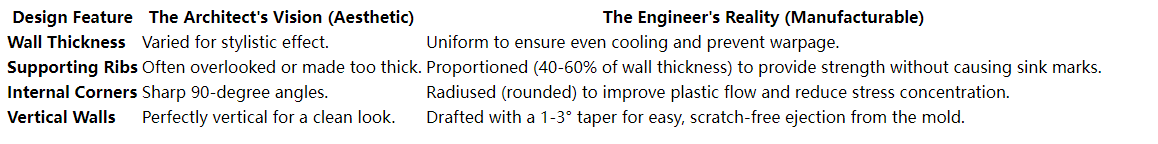

The Architect's Vision vs. The Engineer's Reality

A small adjustment in the design phase can prevent major headaches in production. Our DFM analysis for injection molding is all about bridging this gap.

What Does a Real DFM Report Look Like?

If you've ever received a one-page "report" with vague comments from a potential partner, that's a huge red flag. A proper DFM isn't a simple check; it's a deep, collaborative engineering review.

A DFM report should be a detailed, multi-page technical document that provides specific, data-driven recommendations to improve your design's quality and reduce its cost. The lead engineer at a medical device company told us our DFM report was more thorough than their own internal review, identifying a critical mold flow issue that would have compromised their part's structural integrity.

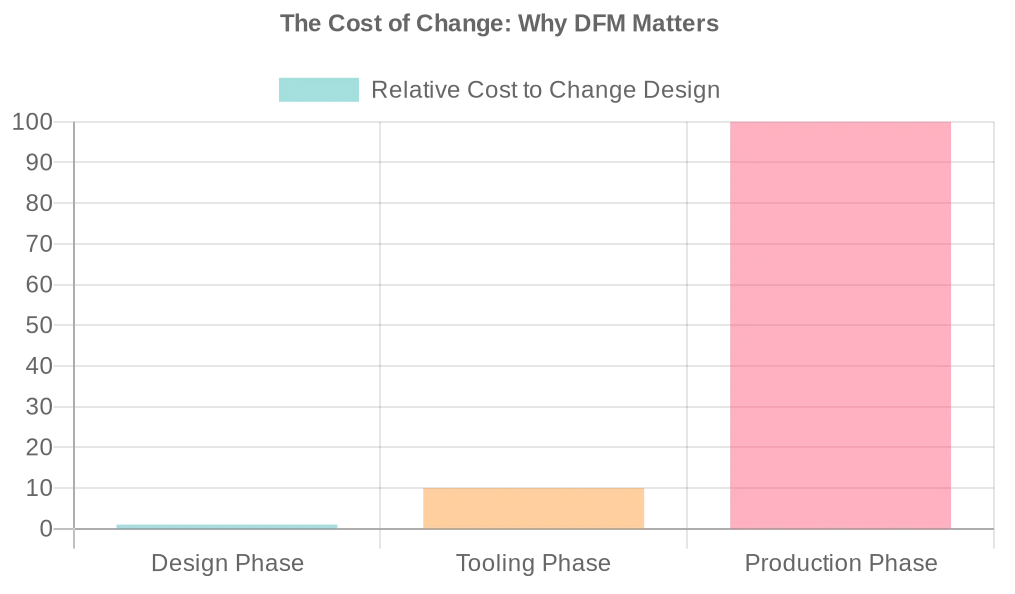

This report is the first and most tangible deliverable of our engineering partnership. It's built on a simple economic reality: the cost of a design change increases exponentially as the project progresses. A simple fix in a CAD file is infinitely cheaper and faster than re-machining a hardened steel mold.

So, what is a DFM report from us? It will always include these four key sections:

- Structural & Mechanical Analysis: We review wall thickness, draft angles, ribs, and bosses to ensure the part is strong and free from cosmetic defects.

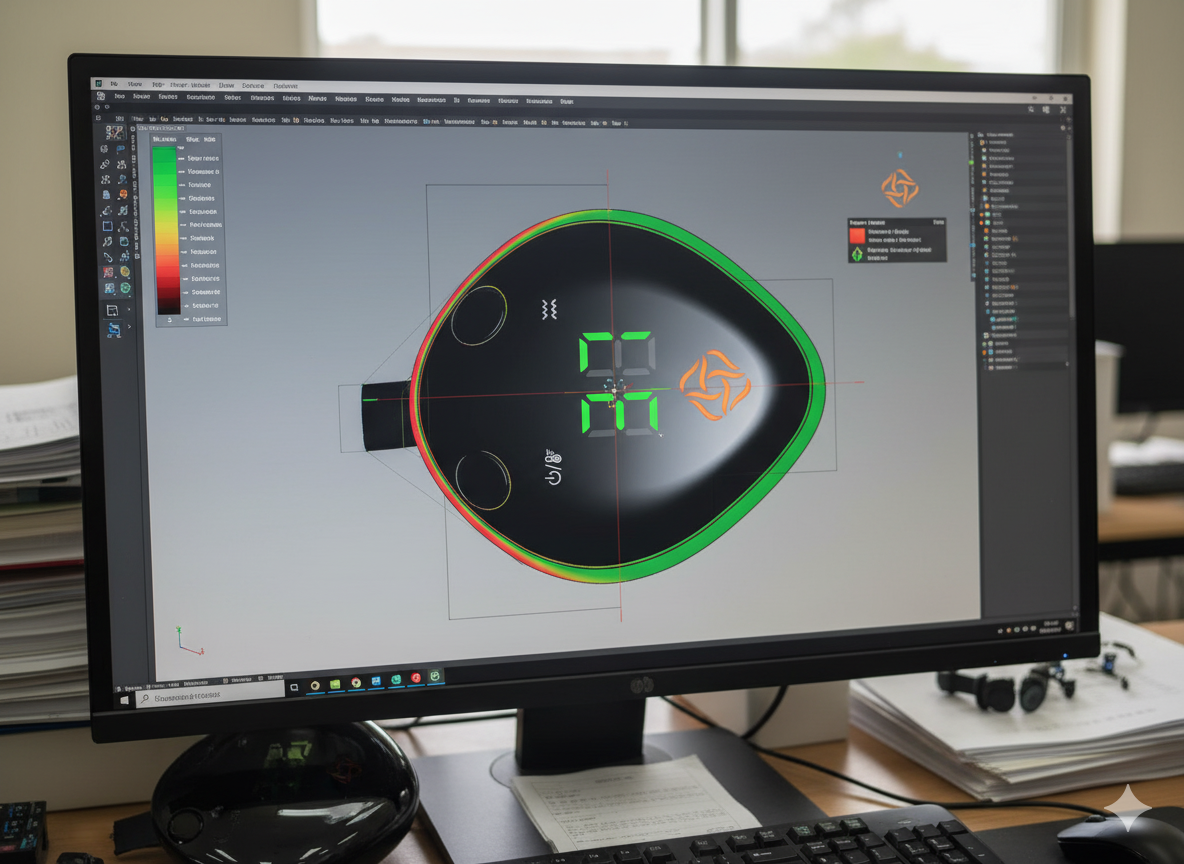

- Mold Design Analysis: We determine the optimal parting line, identify any undercuts, and propose the most efficient gating and ejection strategy.

- Mold Flow Simulation: We provide a visual simulation of how plastic will fill the mold, predicting the location of weld lines and potential air traps.

- Actionable Recommendations: We provide a summary of suggested modifications with clear reasoning, focusing on improving quality, reducing cycle time, and lowering costs.

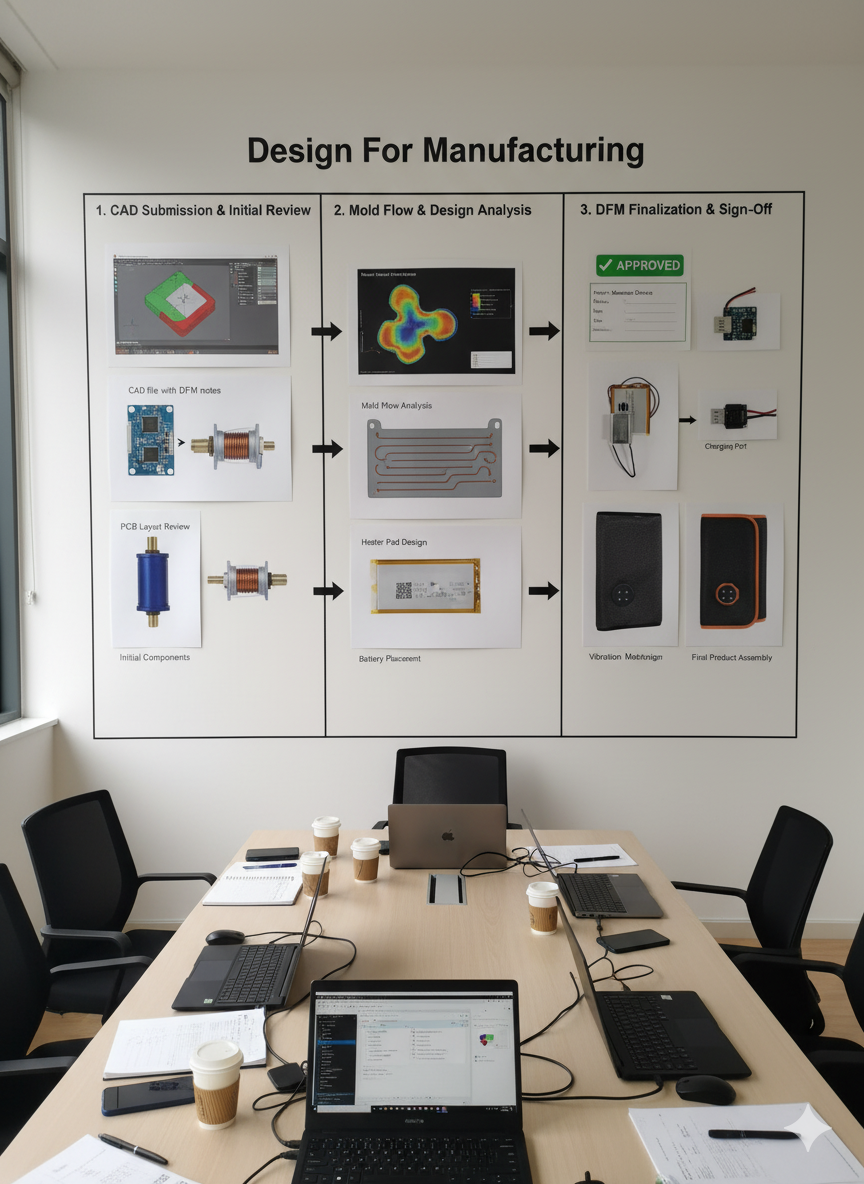

How Our Collaborative DFM Process Works

You need a true technical partner, not just a vendor. You're worried about communication gaps, slow responses, and a lack of transparency during this critical stage.

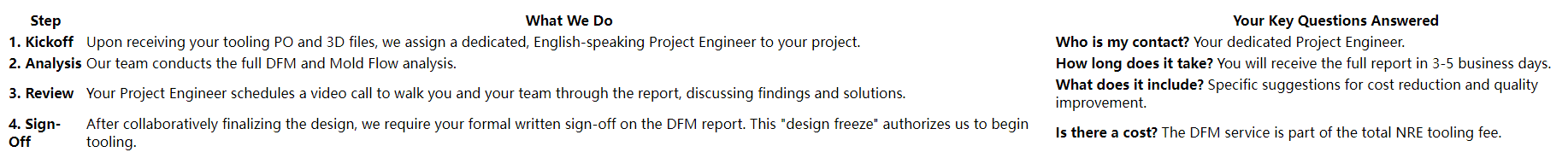

Our process is built for collaboration. We assign a dedicated, English-speaking project engineer to be your direct technical contact, ensuring nothing is lost in translation. This is a professional engineering service that requires significant time and resources. As such, the DFM analysis is conducted as the first step *after* a tooling Purchase Order is placed. Its cost is integrated into the total Non-Recurring Engineering (NRE) tooling fee, ensuring we are both fully committed to the project's success from day one.

The KLCOSY DFM Workflow: Your Questions Answered

A comprehensive Design for Manufacturability (DFM) analysis is the most valuable step in any OEM product development project. It's the moment where the architect's vision and the engineer's expertise converge to create a product that is not only beautiful but also robust, reliable, and profitable. It transforms risk into confidence and sets the stage for a successful, long-term manufacturing partnership. This process ensures your OEM design becomes a market-ready product, built on a foundation of sound engineering and true collaboration.