Massager Logo Application: A B2B Guide to Printing & Engraving

- By Grace

- Updated on

Your brand is your promise of quality, and your logo is its signature. When it's crisp and durable, it communicates premium value. But a logo that fades, scratches, or peels off after six months doesn't just look bad—it cheapens the entire product, turning your symbol of quality into a sign of corner-cutting.

I’ve seen this firsthand. A poorly chosen massager logo application can erode brand equity faster than almost any other cosmetic flaw. The choice of how to apply your logo isn't a minor decorative detail; it's a critical manufacturing decision that impacts your brand's long-term perception. Your logo should be as durable as the product it's on.

This guide will walk you through the primary options for private label massager branding, from the cost-effective standards to the most durable, premium solutions. I'll give you a clear, data-driven comparison of the costs and benefits so you can make a strategic decision that protects your brand for years to come.

So, What Are the Standard Choices?

You need a reliable, cost-effective way to apply your logo, but you're worried about long-term durability. How do you balance your budget with the need for a mark that truly represents your quality standards?

You focus on the two most proven methods: screen printing and laser engraving. A product manager for a high-volume consumer electronics brand told me, "We chose screen printing for its cost-efficiency, but for our pro-level line, we switched to laser engraving. The perceived value and permanence of the laser mark easily justified the small extra cost."

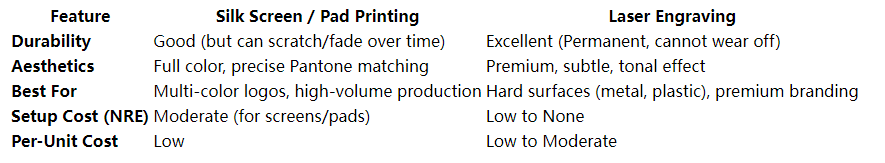

The fundamental trade-off is this: are you adding a layer of ink on top of the material, or are you physically altering the material itself? Each approach has its strengths.

Silk Screening & Pad Printing: The Versatile Workhorse

Screen printing on massagers (and its cousin, pad printing, for curved surfaces) is the industry standard for a reason. We push ink through a fine mesh screen onto your product's surface. It's incredibly versatile, allowing for precise color matching to your brand's Pantone specs, and it's extremely cost-effective at high volumes. However, because the logo is a layer of ink, its massager logo durability depends on adhesion. While modern inks are very tough, they aren't impervious to scratches over the product's lifetime.

Laser Engraving: The Mark of Permanence

Laser engraving on massagers is different. A high-energy laser beam etches the logo directly into the surface, creating a permanent mark that is impossible to wear off. It offers an incredibly premium, high-tech look and feel, typically resulting in a subtle, tonal mark that communicates quality. It's the ideal choice for hard surfaces like metal or dense plastics, where permanence and a premium aesthetic are the top priorities.

Ready for the Next Level? Advanced Options for Maximum Impact

What if your brand requires complex, multi-color graphics or the absolute maximum level of durability? What if the standard options feel like a compromise?

This is where we look to more advanced processes. The head of sourcing for a medical device company put it perfectly: "For our clinical-use products, we can't risk the logo or instructional markings fading. We exclusively use In-Mold Decoration. It's not a logo *on* the part; it's *part of* the part."

UV Digital Printing: Full-Color Photorealism

Think of UV printing as a highly advanced inkjet printer, but for physical products. It applies a fine layer of ink and then immediately cures it with ultraviolet (UV) light, creating a very hard, durable, and scratch-resistant finish. Its biggest advantage is the ability to print full-color, high-resolution graphics, including gradients and photos, without needing multiple screens.

In-Mold Decoration (IMD): The Unbeatable Bond

In-Mold Decoration (IMD) for massagers is the undisputed king of durability. In this process, a pre-printed film with your logo is placed inside the injection mold *before* the molten plastic is injected. The heat and pressure of the molding process cause the graphic to permanently fuse with the surface. The logo isn't on the plastic; it becomes part of the plastic itself, making it completely immune to scratching, fading, or chemical wear.

Here's the Most Important Technical Detail: How to Prepare Your Artwork

You're ready to go, but you want to ensure the final result is as crisp and clear as the design on your screen. What do you need to provide to guarantee the highest quality?

You must provide your artwork in a vector file format. The marketing director for a national retail brand told us, "We used to have quality issues until KLCOSY's team explained the difference between vector and raster. Since we started providing proper vector files, every logo on every product has been perfect."

The quality of your final logo depends entirely on the quality of the source file. This is all about vector vs raster for manufacturing.

- Raster images (like JPG or PNG) are made of pixels. When you scale them up, they get blurry and jagged. This results in soft edges and a loss of sharpness.

- Vector images (like AI, EPS, or SVG) are made of mathematical paths. They can be scaled to any size with zero loss of quality.

For manufacturing processes like screen printing or laser engraving, vector files are essential. They allow our equipment to follow the precise path of your design, resulting in a flawless final product. This is what is the best logo application for plastic and metal surfaces. To ensure the best possible result, always provide your logo in a vector format, with all text converted to outlines and your Pantone color codes clearly identified.

Your logo is the face of your product. The method you choose to apply it speaks volumes about your brand's commitment to quality. By understanding the trade-offs—from the cost-effective versatility of screen printing to the absolute permanence of In-Mold Decoration—you can make a strategic choice that enhances your product's value and protects your brand's reputation. Send us your artwork; our team can provide physical samples on your chosen material to help you make the perfect decision.