Heated Massager Safety: A B2B Sourcing Guide to Liability

- By Grace

- Updated on

As a manufacturer, I've seen firsthand where the sourcing process goes horribly wrong. A procurement manager gets a quote that seems too good to be true. It is. It means they've cut corners on the most critical, invisible part of the product: the thermal safety circuits. A single heated massager recall from a burn incident can bankrupt a brand overnight. This isn't just a hypothetical; consumer product safety data shows thermal issues are a top reason for recalls in our industry.

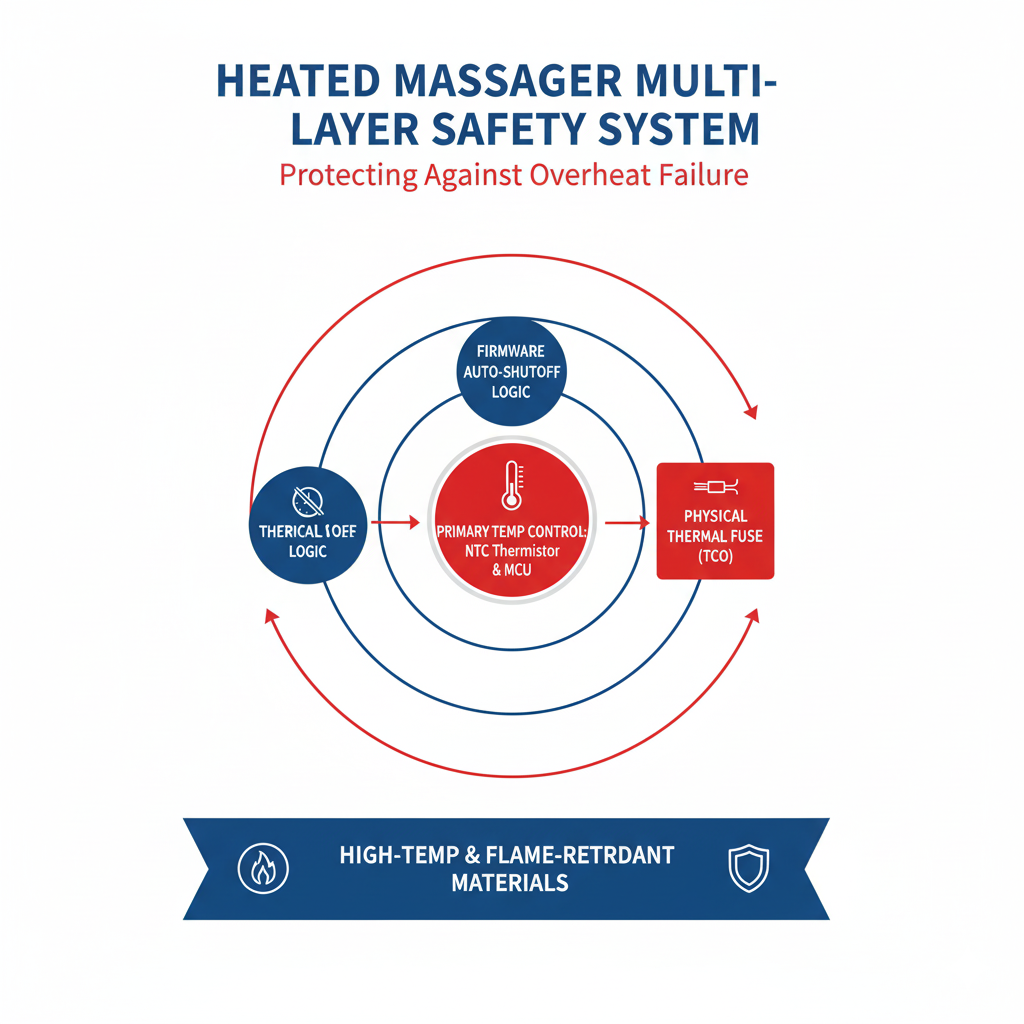

This isn't a risk you can afford to take. It's a liability waiting to happen. That's why we engineer our heating systems with a "defense-in-depth" philosophy, using multiple, redundant layers of safety. We believe that true heated massager safety isn't a feature you add on; it's the non-negotiable foundation you build the entire product on.

Let me show you exactly how we turn your biggest potential heated massager liability into a rock-solid guarantee of safety, backed by documentation and relentless testing.

What’s the First Line of Defense Against Overheating?

You're worried that a faulty device will just keep getting hotter until it becomes dangerous. It’s the most basic failure, and preventing it requires a smart, active control system, not just a simple on/off switch.

I remember a retail partner who was launching in a major department store and faced a brutal safety audit. Our comprehensive documentation on the NTC thermistor and the 15-minute auto-shutoff was the key to their immediate approval. They got on the shelves weeks ahead of their competitors who were stuck in compliance limbo.

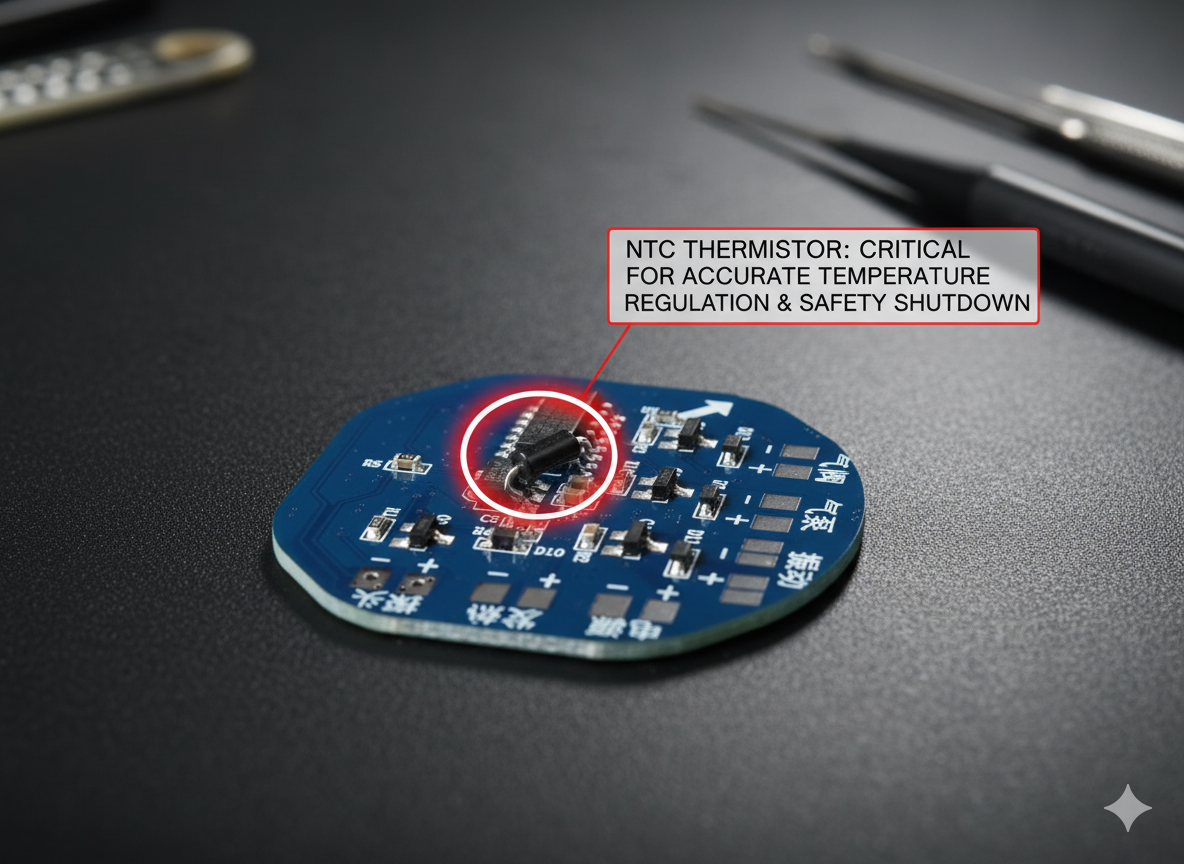

Our first layer of protection is an active, intelligent temperature management system. At its core is a high-precision NTC (Negative Temperature Coefficient) thermistor in massagers, which constantly monitors the heating element. It provides real-time temperature feedback hundreds of times per second. We program a strict maximum temperature into the firmware—typically 45°C (113°F), a level that's therapeutic but well within international safety standards. If the thermistor senses the temperature even approaching this limit, the controller automatically dials back the power to maintain a stable, safe warmth.

As a second active safeguard, we build a mandatory 15-minute auto-shutoff massager timer directly into the firmware. This prevents any risk from prolonged, unattended use—a critical feature for users who might fall asleep while using the device.

What Happens if the Primary Controls Fail?

Okay, but you're a supply chain expert. You know that any system can fail. A software bug, a component failure—what's the backup plan? A single point of failure is completely unacceptable when it comes to thermal safety for massagers. You need a failsafe that works 100% of the time, no matter what.

This is where our second, and most critical, layer of defense comes in: a physical, non-resettable thermal cutoff (TCO) fuse for massagers. Think of it like the emergency brake on a train. This is a purely mechanical component hardwired directly to the heating element. It's designed to physically and permanently break the circuit if it ever detects a temperature that exceeds a safe threshold (e.g., 65°C). It’s a sacrificial failsafe. If the primary software controls were to fail for any reason and the device began to overheat, the TCO fuse would trip and irreversibly disable the heating function. The device is now permanently safe.

This isn't a resettable switch. Its only job is to be the ultimate guarantor of safety. We couple this with careful material selection, using high-temperature-grade plastics like Polycarbonate (PC) to ensure that even in a worst-case scenario, the device's housing will not deform or melt.

Our Multi-Layered Safety Protocol

Our safety philosophy is built on redundancy. Each layer is designed to back up the others, creating a system that is virtually fail-proof.

How Do We Prove This Safety for Every Single Unit?

A "golden sample" that works perfectly is one thing. But how can you be sure that the 10,000th unit coming off the assembly line has the same bulletproof safety protections? Without a rigorous and verifiable QC process, you're just crossing your fingers.

Hope is not a strategy. We guarantee safety through a multi-stage, 100% mandatory QC protocol. First, every single unit undergoes a functional test on the assembly line. The device is powered on, the heating function is activated, and we use a thermal probe to verify that it heats to its target temperature and stabilizes correctly. We also verify that the 15-minute auto-shutoff timer works perfectly.

Second, for every production batch, we conduct "abnormal condition" testing on a random sample. This is where we deliberately stress-test the failsafe systems, for example, by running the device while it's wrapped in a towel to simulate a worst-case scenario. The goal of this test is to force the TCO fuse to trip, confirming that the ultimate failsafe is working as designed. We provide you with all the documentation: the spec sheets for the certified fuses and thermistors we use, and our own internal QC reports that show a 100% pass rate for your production batch.

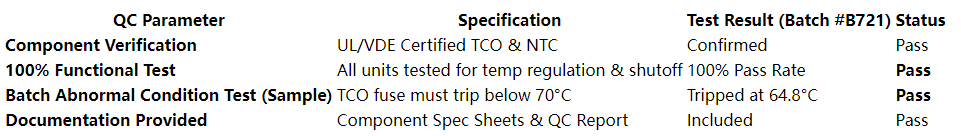

A Look at Your Thermal QC Report

This is a simplified version of the compliance report you get with every shipment. It provides a clear, data-driven audit of our safety checks for your production run.

Heating safety isn't just a feature; it's a promise. When sourcing safe heated massagers, a deliberate, multi-layered engineering and testing process is the only way to operate. We built our reputation on this process, and it allows us to provide a guarantee of safety that you can pass on to your customers with absolute confidence. Your brand's safety is our brand's safety.

If you're ready to partner with a manufacturer who treats your safety as their own, contact our team. We'll be happy to provide you with a full technical file and third-party compliance reports for our heating systems.