How to Eliminate RoHS Compliance Risks and Secure Your Supply Chain

- By Grace

- Updated on

It’s the nightmare scenario I discuss with every new partner. Picture this: Your new product line is a hit. Sales are climbing, reviews are glowing, and your brand is gaining real traction. Everything feels perfect. And then, the notification drops. It’s not a customer complaint about a broken button. It’s an official notice from a regulatory agency. They’ve conducted a random market screening and found a restricted chemical—one you’ve likely never heard of—testing 0.1% over the legal limit.

In an instant, that success story evaporates. You are legally barred from selling your inventory. You are facing a mandatory product recall, significant fines, and the dismantling of your brand's reputation. This isn't a defect you can see or touch. It’s a silent, invisible threat buried deep in your supply chain—a ticking time bomb that just went off.

This is the harsh reality of environmental compliance in today's global market. Regulations like RoHS (Restriction of Hazardous Substances) aren't just bureaucratic paperwork; they are the gatekeepers of market access and a non-negotiable pillar of supply chain risk management. At KLCOSY, my philosophy is simple: true partnership isn't about promising compliance; it's about engineering a transparent system that defuses this bomb before the product ever leaves our factory.

So, What Is This 'Silent Killer' Hiding in Your Supply Chain?

I recall a conversation with a client, a major distributor of corporate wellness products, who shared a horror story about a competitor. This competitor was hit with a massive fine and a forced recall in Germany. The culprit? The paint on a tiny capacitor, buried deep inside the device, contained a restricted flame retardant. Their supplier had provided a generic "certificate," but without a verifiable system behind it, that piece of paper was worthless.

The RoHS directive, which originated in the EU, has effectively become the global standard for managing hazardous substances in electronics. It strictly restricts toxic materials like Lead (Pb), Mercury (Hg), Cadmium (Cd), and certain phthalates. I always remind my clients: failing to comply isn't a minor infraction; it is a legal declaration that your product is unsafe.

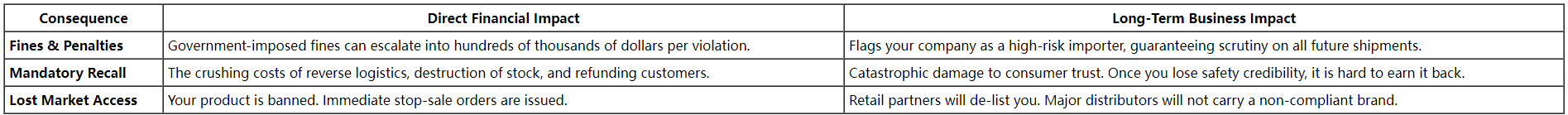

The fallout from a RoHS failure is not a risk "probability"—it is a financial certainty. The consequences trigger a multi-front crisis that many brands never fully recover from.

Key Takeaway: Compliance is binary. You are either safe, or you are out of business. There is no middle ground.

How Do You Stop a Ticking Time Bomb You Can't Even See?

The terrifying part of RoHS is its invisibility. You cannot judge a circuit board's safety by looking at it. Your product's compliance relies entirely on the integrity of hundreds of individual components. So, how do you control what happens deep in the sub-tiers of manufacturing? The only answer is rigorous supplier verification.

One of our partners recently needed detailed material declarations for their internal ESG reporting. Because we maintain a systematic "Compliance Chain of Custody," we provided the component-level data they needed within 48 hours. It turned a potential panic into a demonstration of competence for their leadership team.

To guarantee the safety of the final product, we build a fortress of verification around our supply chain. Here is the three-stage process we use to ensure non-compliant components never touch our production line:

- The Supplier Vetting Mandate: Our process begins before a purchase order is ever written. Every potential raw material supplier must pass a strict qualification audit. A core requirement is submitting valid, up-to-date RoHS documentation, including third-party test reports. If a supplier cannot prove their safety, they cannot work with us.

- The Material Declaration Chain: We don't rely on old data. For every production run, we track the specific Bill of Materials. We require a formal Certificate of Compliance for that specific batch of components. We don't accept generic promises; we demand batch-specific accountability.

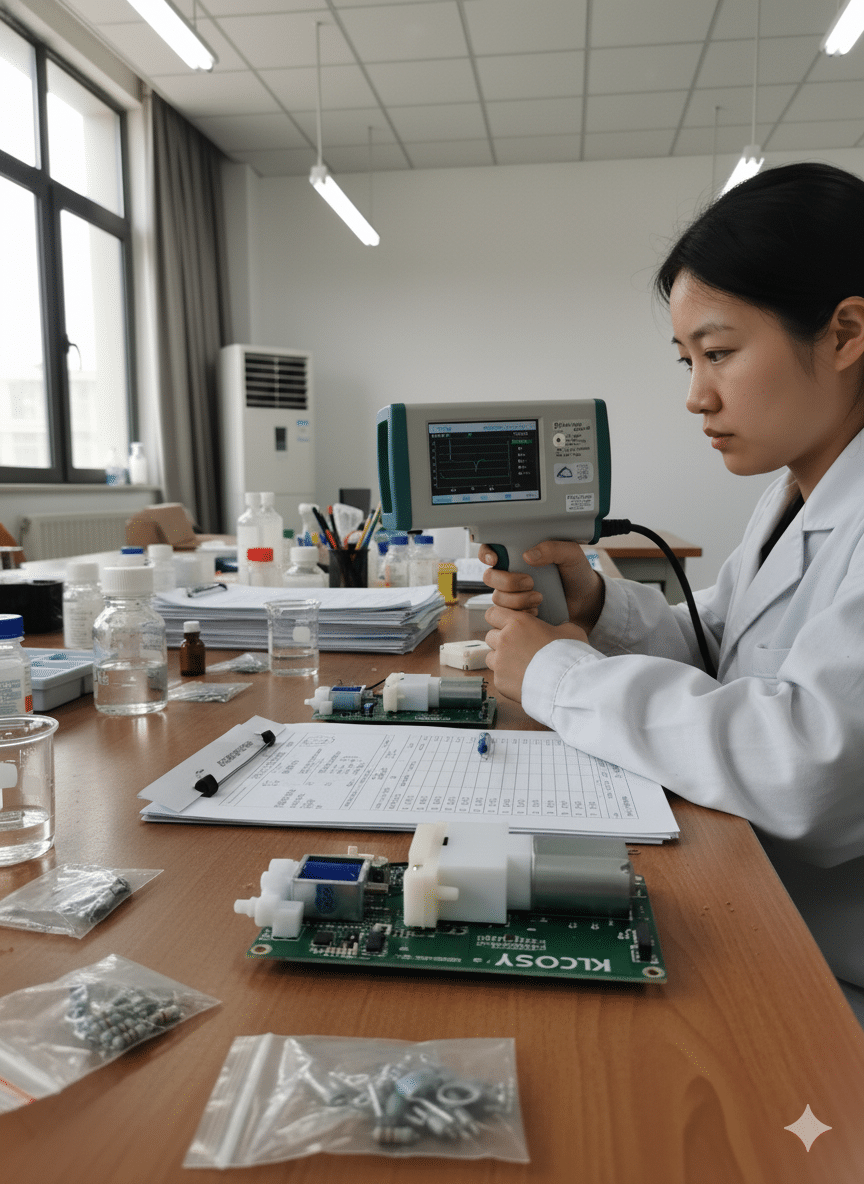

- The "Trust but Verify" Protocol: Paperwork is necessary, but physics is the final judge. We employ random XRF (X-ray Fluorescence) screening and periodic third-party lab testing on high-risk components. We assume nothing until the test results confirm it.

At the end of the day, your sleep is as important as your sales. Compliance shouldn't be a source of anxiety; it should be a given. By prioritizing transparency and rigorous verification, we ensure that your brand is built on a foundation that is safe, legal, and ready for the global stage.

Don't let an invisible risk destroy visible success. Reach out to me, and let’s discuss how we can secure your supply chain against the hidden threats of the global market.