Third-Party Inspection: A B2B Guide to Massager Supplier Verification

- By Grace

- Updated on

You're thousands of miles away from the factory floor. You’ve approved the samples and the in-house QC reports look good, but one big question remains: how can you be absolutely certain that the thousands of units packed and ready for shipment meet your exacting quality standards? The financial risk of shipping an entire container of goods without independent verification is immense.

This is the moment where trust has to be verified. The single most powerful tool for this is a Pre-Shipment Inspection (PSI) conducted by your own chosen third-party agency. At KLCOSY, we don't just tolerate this scrutiny; we welcome it. We believe a third-party inspection isn't a sign of mistrust, but the final, critical step in a truly transparent and collaborative partnership.

This guide will walk you through our "red carpet, not red tape" procedure for accommodating your inspectors. I'll explain exactly what happens if they find an issue and clarify our commitment to accountability, ensuring you have the ultimate peace of mind before your product ever leaves our doors.

How Do We Make Third-Party Inspections Seamless?

You've hired an inspection agency, but now you're worried about the logistics. Will the factory be cooperative? Will your inspectors have the access they need to do their job properly, or will they face delays and obstructions that compromise their report?

Our entire process is built to be an open book. We treat your inspector as a welcome guest and a vital part of the massager quality inspection process. The Quality Manager for a major German distributor told me, "My inspector from SGS said your team was the most organized and transparent they'd ever worked with. They had the goods ready, provided a proper workspace, and gave them full access without interference. It made the entire process faster and the report more reliable."

Our goal is to facilitate a smooth and effective inspection. We have a standard operating procedure designed to eliminate friction and ensure your chosen agency can perform its duties to the highest standard. We see your inspector not as an adversary, but as a partner in confirming that the product meets our shared standards. This is a core part of our private label quality assurance program.

Our 4-Step "Red Carpet" Inspection Protocol

- Simple Scheduling: To schedule an inspection, we just need a minimum of five business days' advance notice. This allows us to ensure the goods are 100% produced and ready. Just give us your agency's contact details, and we'll coordinate the final date and time directly.

- Defining the Scope: You provide your inspection agency with your specific quality standards and the AQL (Acceptance Quality Limit) you require. They, in turn, share this inspection protocol with us so we are all on the same page.

- Execution Day - Full Access: On the day of the inspection, we provide your agency with a dedicated, well-lit workspace. Your inspectors will have full and unfettered access to the goods to perform all necessary checks without interference.

- Transparent Reporting: The final report from your agency should be sent to both of us simultaneously. This ensures all stakeholders have the same objective data to work from.

So, What Happens if an Inspection 'Fails'?

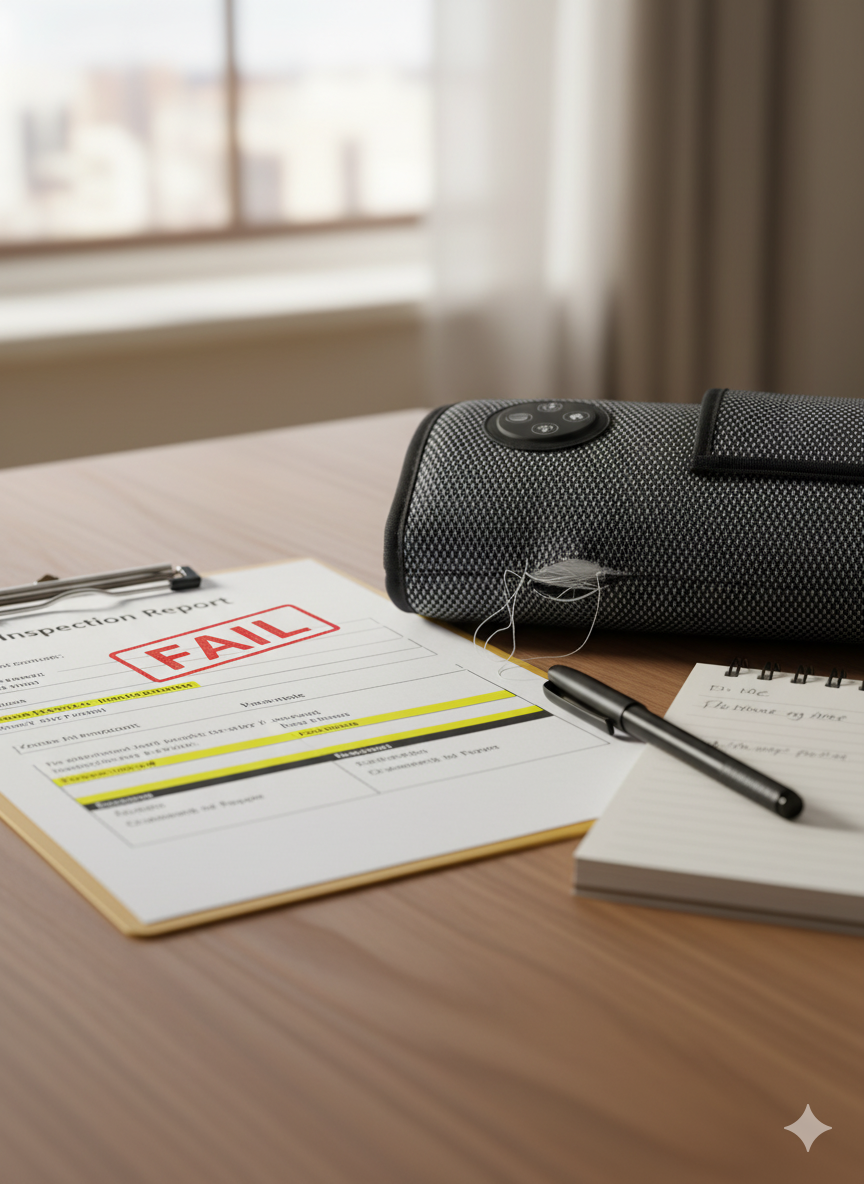

The inspection report lands in your inbox, and the final verdict is "FAIL." Your heart sinks as you imagine a long, difficult negotiation with your supplier, causing massive delays to your launch.

For us, a "failed" inspection isn't a conflict; it's a critical data point that triggers an immediate and structured response. The shipment is put on hold, and we immediately begin a collaborative analysis of the report. I remember the purchasing manager for a large online retailer had a shipment fail due to a minor cosmetic defect rate that was slightly above their AQL. She told me, "I was bracing for a fight. Instead, your team didn't argue. They owned it, presented a plan for a 100% re-sort and rework within 24 hours, and kept our launch on track." This is our supplier verification promise in action.

So, what happens if a factory inspection fails? A "FAIL" verdict simply means that the inspector found a number of major or minor defects that exceeded the statistical limits you defined. Our response is not defensive; it is procedural. The goal is to understand the root cause, correct the issue, and verify the solution as quickly and transparently as possible.

Our Post-Failure Resolution Protocol

- Immediate Containment: The entire shipment is immediately quarantined. No goods will be shipped until the issues are fully resolved.

- Joint Analysis of the Report: Your dedicated Account Manager will schedule a call with you to review the inspector's findings in detail. We want to understand what they saw, exactly as they saw it.

- The Corrective Action Plan (CAP): Within 48 hours, we will present you with a formal Corrective Action Plan. This document will detail the root cause of the failure and the specific steps we will take to fix it.

- Execution and Re-Verification: Once you approve the CAP, our team executes the rework. The final step is a re-verification to confirm the issue has been resolved, which often involves a re-inspection.

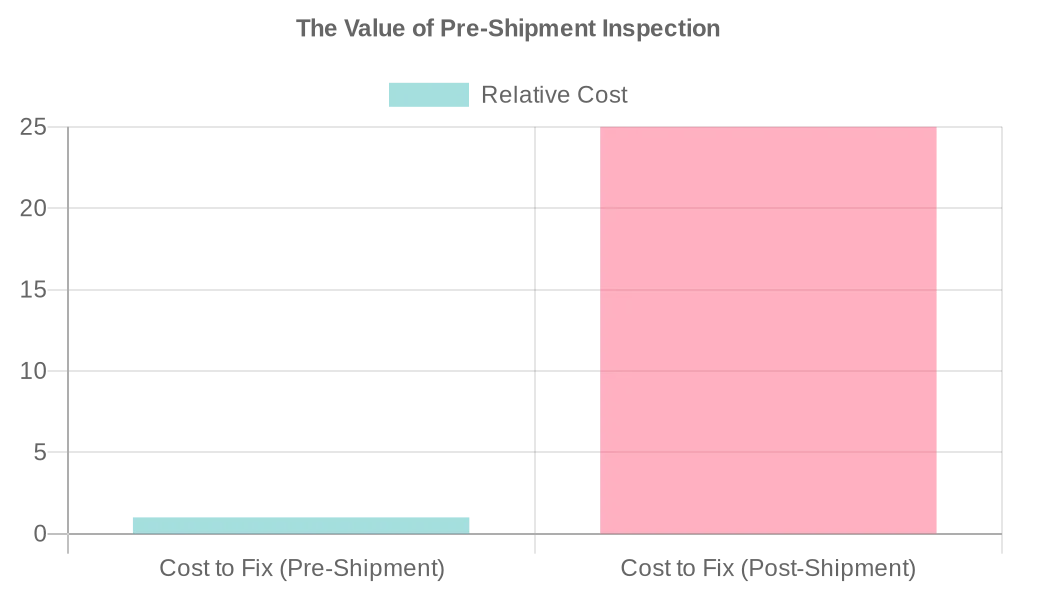

This process underscores the immense value of a PSI. Finding and fixing a problem in our factory is exponentially cheaper and faster than dealing with a product recall.

And Finally, Who Pays for the Re-Inspection?

The shipment failed, the goods have been reworked, and now you need to verify the fix. But that means paying your inspection agency for a second visit. It feels unfair to pay for an extra cost that was caused by your supplier's mistake.

We agree. Our partnership is built on accountability. If the initial inspection fails due to a quality issue that was clearly our factory's fault, we will cover the reasonable cost of the re-inspection. A corporate gift supplier had a shipment fail due to incorrect accessory packing. He told me, "I was expecting a fight over the re-inspection fee. Instead, my KLCOSY account manager just said, 'That was our mistake. Of course we'll cover it. Just send us the invoice.' That's what a true partnership looks like."

Our policy on who pays for re-inspection is rooted in the principle of "Right First Time." Our own internal Final Quality Control (FQC) system is designed to catch any and all issues before your inspector ever arrives. If we fail in that duty, the responsibility is ours. We see covering the re-inspection fee not as a penalty, but as a standard business practice that demonstrates our commitment to our quality promises. It ensures that our goals are perfectly aligned: to produce a flawless shipment that passes inspection the first time, every time.

A third-party inspection should not be a source of conflict, but a source of confidence. By embracing a process of radical transparency, seamless cooperation, and full accountability, we transform the pre-shipment inspection from a stressful audit into a valuable, collaborative verification. It is the final quality gate that protects your investment, your brand, and your customers. A reliable manufacturing partner shouldn't fear this final check; they should welcome it as proof of their commitment.