Massager Production Capacity: A Guide to Peak Season Sourcing

- By Grace

- Updated on

The calendar flips to August, and that familiar knot of anxiety starts to form in your stomach. It's the peak season scramble. Will your supplier deliver your critical holiday shipment on time, or will your brand become another cautionary tale of over-promising and under-delivering? For a seasonal business, a missed shipment isn't just a delay; it's a catastrophic loss of revenue.

At KLCOSY, we don't believe in just hoping for the best during peak season manufacturing. We’ve replaced guesswork and empty promises with a transparent, data-driven Capacity Management System. We see our production capacity not as a vague marketing number, but as a predictable, manageable asset that we plan and allocate in partnership with you.

In this guide, I'm going to pull back the curtain on our factory's real production capabilities. I'll break down exactly how we manage and prioritize orders during the pre-Christmas rush and, most importantly, show you how we can work together to guarantee your holiday season private label supply chain is a source of certainty, not stress.

So, How Do You Tell Real Capacity from Empty Promises?

Ever been told a factory has a capacity of 100,000 units a month, only to have your 20,000-unit order show up late? You were given a big number, but what you really needed was a solid commitment. The problem is the massive gap between what a factory *could* produce in a perfect world and what it *can* produce consistently, day in and day out.

The sourcing director for a major North American retailer told us their previous supplier's massager production capacity was a fantasy number that didn't account for maintenance or bottlenecks. They switched to us for the predictability our planning provides.

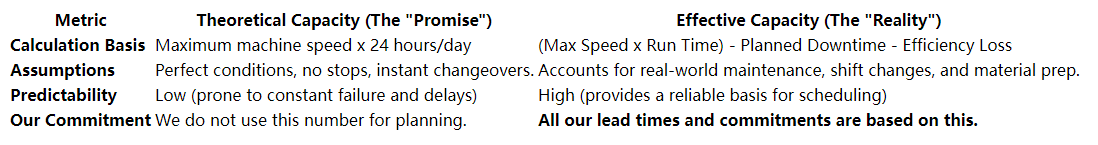

Many factories love to quote their "Theoretical Capacity"—the absolute maximum number of units they could produce if machines ran 24/7 with zero downtime. It's an impressive number on a spreadsheet, but it's completely disconnected from reality. At KLCOSY, we plan our business and make promises based on our Effective Capacity. This is the real, sustainable output we can achieve after accounting for planned maintenance, machine changeovers, and historical efficiency rates. For a standard portable massager, our realistic, sustainable monthly production capacity is approximately **80,000 units** during the off-season. It might not be the biggest number you'll hear, but it's the most honest one.

Theoretical vs. Effective Capacity: A Realistic Breakdown

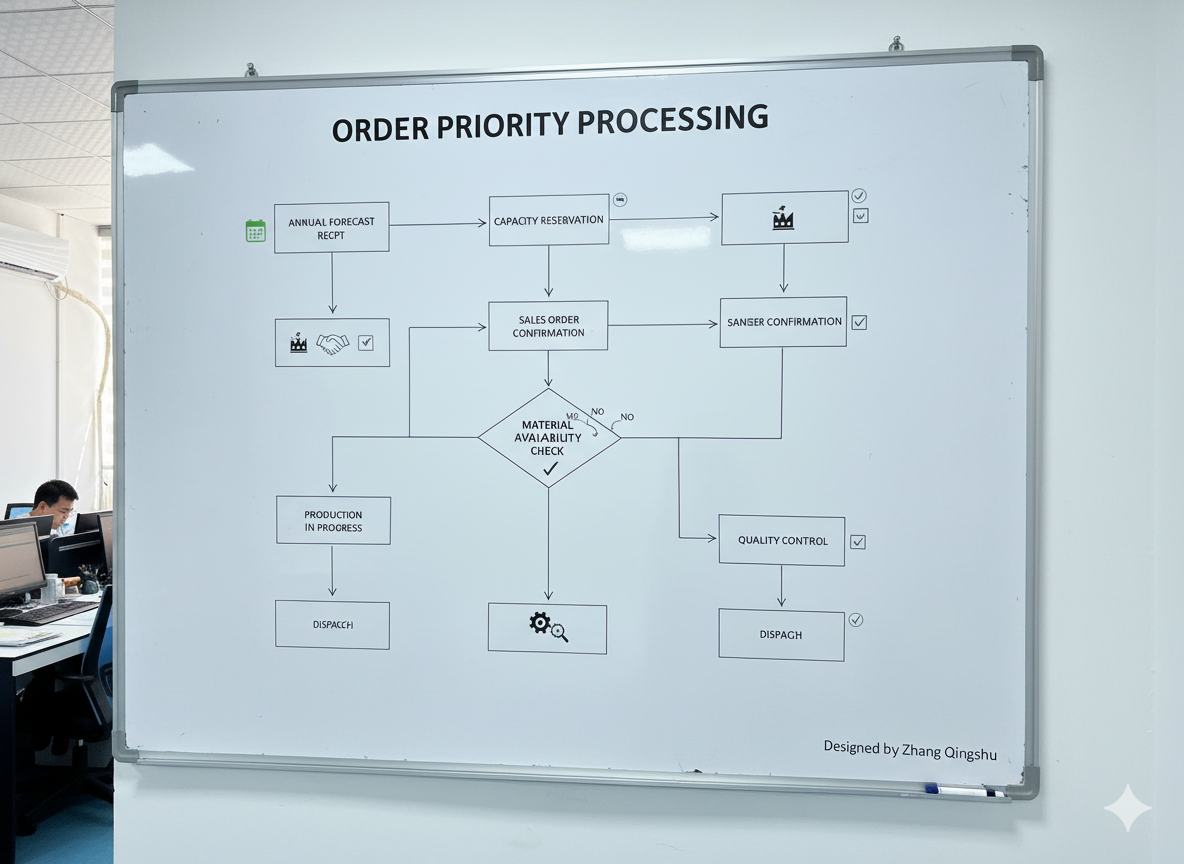

How Is My Order Protected During the Holiday Rush?

It’s October. Every brand is demanding its pre-Christmas inventory. How do you know your shipment won't be pushed back for a larger, louder customer who placed their order at the last minute?

Your order is protected by a disciplined scheduling system, not by who shouts the loudest. I was talking to a European distributor who gives us an annual forecast, and he said something that stuck with me. He said our supplier capacity management system gives him 'peace of mind.' They know their production slots are locked in, even when last-minute rush orders come in from other clients. That's what we're aiming for.

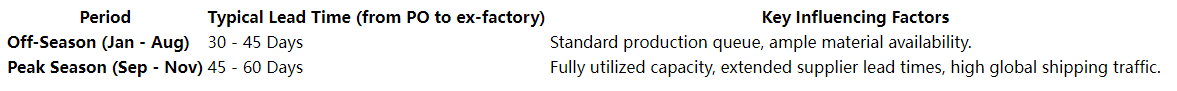

During peak season—typically from September to late November—our manufacturing lead times naturally extend. This isn't chaos; it's a fully booked and meticulously managed production schedule. To meet this surge, we don't just work harder; we plan smarter. Our strategy is built on proactive resource planning, flexible staffing with approved overtime, and transparent scheduling managed through our ERP system.

Peak Season vs. Off-Season: A Transparent Look at Lead Times

This transparency allows you to build realistic timelines for your holiday season sourcing, replacing uncertainty with a predictable schedule. The single best way to secure your place at the front of this queue is to move from being a reactive order-placer to a proactive planning partner.

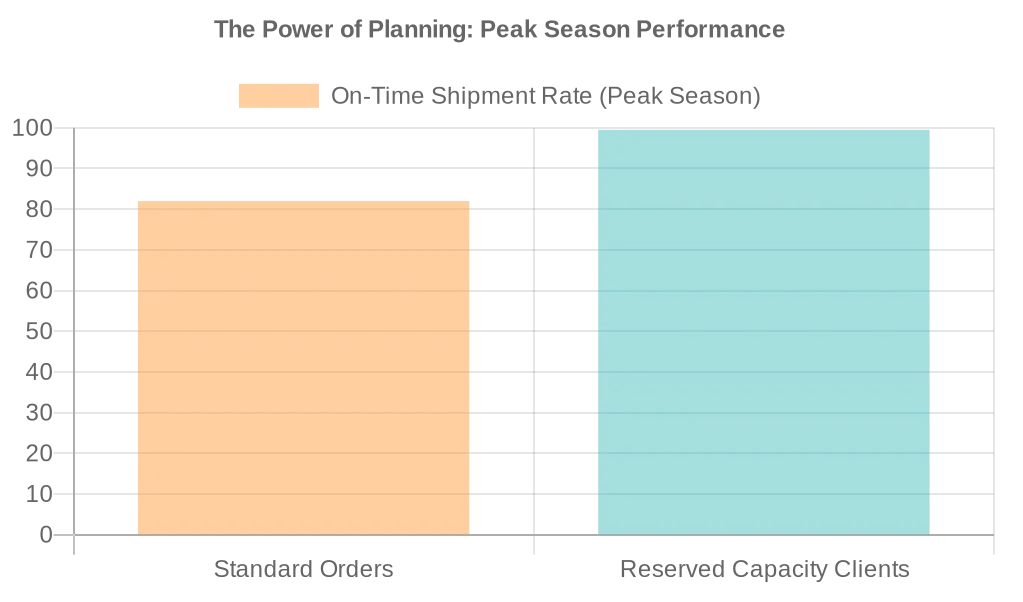

So, How Can I *Guarantee* My Holiday Shipment Capacity?

You've submitted your holiday forecast, but in a busy market, a forecast can feel like a hopeful wish. How do you turn that wish into a concrete, non-negotiable production slot you can build your business around?

You do it through our Capacity Reservation Program. It's a simple, formal agreement. A mutual commitment. It transforms your forecast from a hopeful wish into a guaranteed manufacturing slot. I remember the founder of a fast-growing online brand telling me, "The ability to guarantee production capacity for Q4 back in July was the single biggest factor in our record-breaking holiday season. It just eliminated all the supply chain stress."

The Capacity Reservation Program is designed for partners who require absolute certainty. You provide us with a firm Purchase Order based on your forecast by an agreed-upon deadline (e.g., end of Q2 for Q4 delivery). In return, we contractually guarantee your production slot. More than that, we use your commitment to get ahead of the peak season rush by immediately ordering all the critical, long-lead-time components for your build.

Benefits of the Capacity Reservation Program:

- Locked-In Lead Time: Your production slot is guaranteed, giving you a firm, predictable ex-factory date.

- Guaranteed Material Availability: We secure your components before the peak season price hikes and shortages begin.

- De-Risked Launch: It eliminates the single biggest variable in a seasonal product launch—production uncertainty.

- Priority Status: You are not just in the queue; you are a foundational part of our planned production, with resources allocated and ring-fenced specifically for your order.

This program is the ultimate expression of our factory capacity planning philosophy. It transforms our relationship from a simple buyer-supplier transaction into a strategic partnership focused on mutual success.

In modern manufacturing, predictability is the new currency. The most valuable asset a supplier can offer during peak season isn't just a large capacity number, but a transparent and reliable system for managing that capacity. Our commitment to planning based on Effective Capacity, a disciplined scheduling process, and our proactive Capacity Reservation Program are all designed to provide you with the one thing you need most for your critical selling season: certainty. A strategic manufacturing partner can turn the stress of peak season into a predictable and profitable period for your brand.