ODM Mold Development: A B2B Guide to Process, Cost & Ownership

- By Grace

- Updated on

You’ve finalized a brilliant product design. Now comes the most critical and often most opaque investment you'll make: the injection mold. For many businesses, this stage is a "black box" of vague timelines, hidden costs, and uncertain ownership. You send a large payment across the world and just hope for the best, with very little control or visibility.

This uncertainty is a massive business risk. I've seen partners come to us after being burned by shifting deadlines and surprise fees from other suppliers, which completely derailed their product launch. At KLCOSY, we treat ODM mold development not as some mysterious art, but as a transparent, data-driven engineering project. We provide a clear blueprint, so you know exactly what to expect in terms of timeline, cost, and ownership.

This guide will demystify our injection mold process. I’ll break down the realistic costs and timelines, clarify your ownership rights, and explain how we manage the risks of delays and design changes, giving you the predictability you need to invest with confidence.

What is the Realistic Timeline and Total Cost for a New Mold?

You're trying to build a project budget and a go-to-market timeline, but your supplier gives you a vague range of "30 to 60 days" and a cost that seems to change with every conversation. This lack of precision makes any real planning impossible.

A predictable project requires a detailed, phase-based plan. A brand owner for a new line of ergonomic accessories told us, "For the first time, a manufacturer gave us a fixed NRE cost and a timeline with clear milestones. We could finally build a reliable business plan around it."

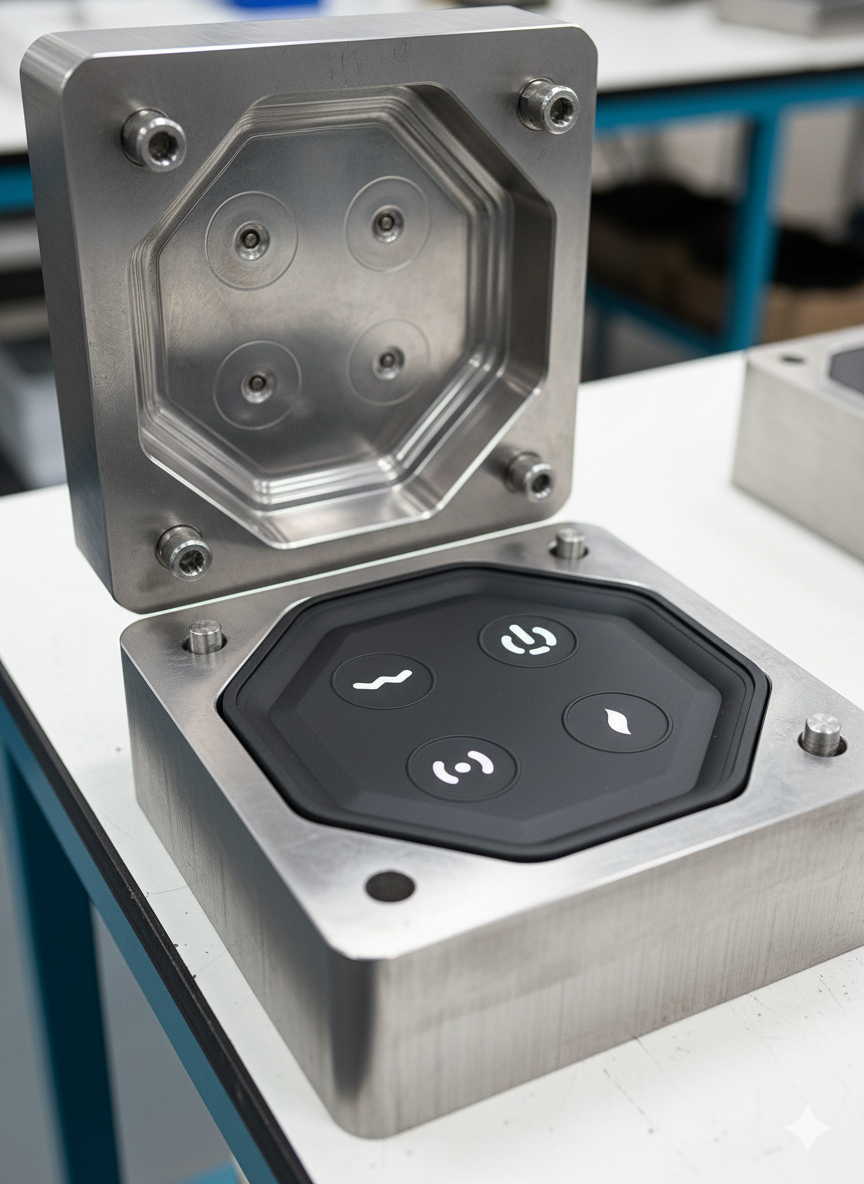

The massager tooling cost and timeline are not arbitrary; they are the direct result of specific engineering choices. The key variables are the mold's complexity and the type of steel used. Our process begins with a comprehensive Design for Manufacturability (DFM) analysis, where we identify any potential production issues with your design *before* we cut any steel. This proactive step saves enormous time and money by preventing costly modifications down the line.

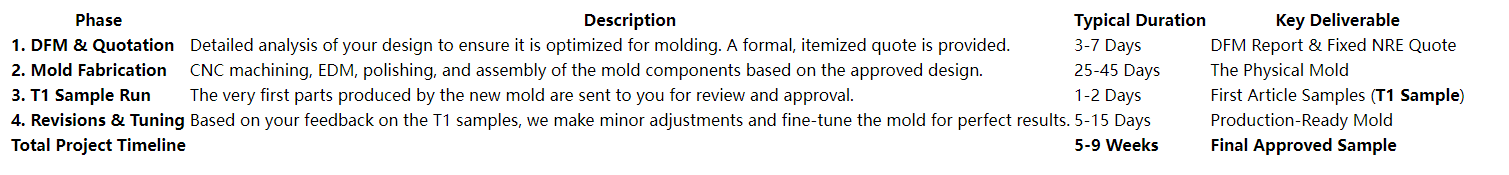

Our Transparent Mold Development Blueprint

Our process is broken into clear, sequential phases, each with a defined timeline. This allows you to track progress against key milestones and removes the guesswork from your project planning.

So, If I Pay for the Mold, Do I Own It Exclusively?

You've invested tens of thousands of dollars in tooling, a critical asset for your business. But is it truly yours? Many suppliers have vague terms that can prevent you from moving your mold if you ever need to switch partners.

The answer should be an unequivocal yes. Your investment means exclusive ownership. A European distributor told us our private label mold ownership clause was a deal-maker. They had been trapped with a failing supplier previously because they didn't have clear ownership of their most valuable asset.

This is one of the most critical but often overlooked aspects of an ODM partnership. At KLCOSY, our position is simple: when you pay the Non-Recurring Engineering (NRE) fee for a mold, you are purchasing a physical asset that belongs to your company. This is legally codified in our supply agreements. The agreement clearly states your exclusive ownership, your right to inspect the mold, and your right to transfer it to another facility at your request. We see ourselves as the custodians of your asset, responsible for its maintenance and secure storage, but you are always the owner.

De-Risking Your Most Important Asset

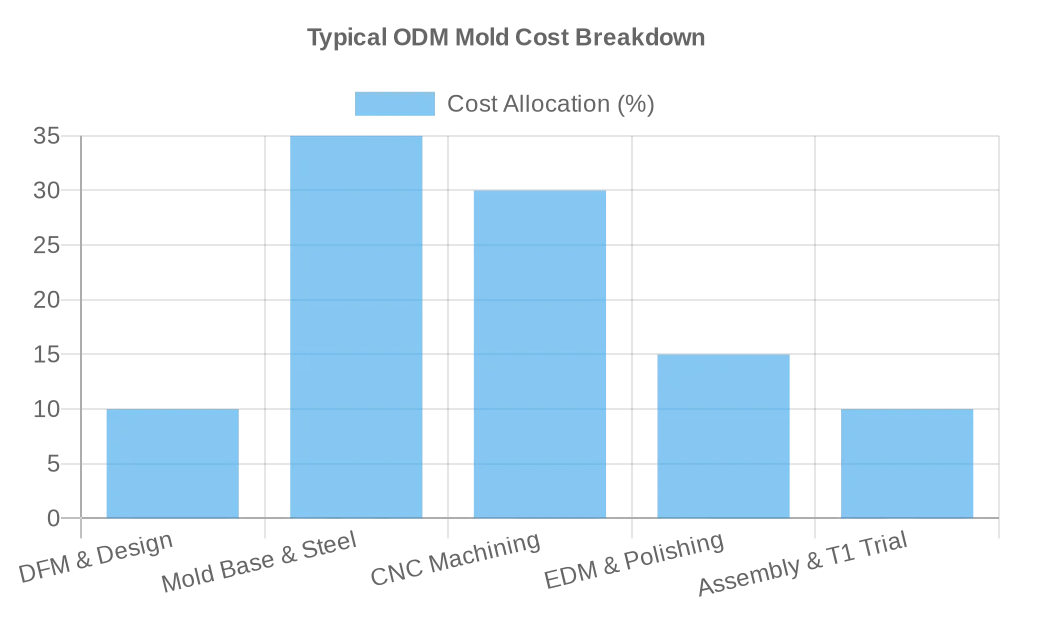

To provide complete transparency, our formal quotation includes a detailed breakdown of the mold itself, so you know exactly what you are paying for.

This level of detail ensures there are no ambiguities. You are not just buying a "mold"; you are investing in a precisely specified piece of industrial equipment with a guaranteed lifespan, and you have the contractual paperwork to prove it's yours.

How Are Delays and Design Changes Handled?

The two biggest fears in mold development are unexpected delays and the massive costs of making a design change after the mold is already built. How do you manage these risks?

We manage them with contractual accountability and a transparent change-management process. Our agreements include financial penalties for unexcused delays on our part. A project manager for a startup launching their first hardware product told us our clear process for handling design changes saved their project. They knew the exact cost and time impact upfront, which allowed them to make a smart business decision.

Managing the Inevitable: The Engineering Change Order (ECO)

What happens if you receive the T1 samples and realize you need to make a design modification? While this is always more costly than getting the design right during the DFM phase, we have a structured and transparent process for handling it with an Engineering Change Order (ECO).

- Impact Assessment: You submit a formal ECO detailing the required change. Our tooling engineers then conduct a thorough impact assessment.

- Formal Quotation: We provide a detailed quote outlining the exact cost and time delay. For a minor change, this might be a few days of laser welding. For a major change, it could require a new core or cavity insert.

- Client Approval: No work begins, and no costs are incurred, until you have reviewed the quotation and given your formal written approval.

This process removes the fear of "blank check" changes. You are always in control, with a clear understanding of the cost and schedule implications before you commit to a modification.

Investing in an ODM mold should be a transparent and predictable step in your product launch, not a gamble. By providing a clear blueprint for the timeline, a detailed breakdown of costs, guaranteed exclusive ownership, and a structured process for managing risk, we eliminate the uncertainty from this critical process. This transforms the "mold mystery" into a manageable engineering project, allowing you to focus on what you do best: building your business.